Enhancing Precision in Oil and Gas Well Stimulation Design

With StimDesigner, you can get accurate well stimulation prediction results. We specialize in matrix stimulation and customize our services for your extended reach (ERD) and maximum reservoir contact (MRC) wells. Enhance your production and improve your returns with our oil and gas well stimulation services.

StimDesigner Overview

A Tool for Modeling Matrix Stimulation Operations in Extended Reach Wells

StimDesigner is a niche tool for modelling matrix stimulation operations on extended reach wells completed with inflow control devices or limited entry liners. It can also be used for the simpler scenarios of vertical or deviated wells completed as openhole or cased hole.

Matrix stimulation is an operation, performed by injecting different formation stimulating fluids, to improve well productivity or injectivity.

By removing formation damage, caused by drilling and/or other foreign fluids, matrix stimulation either restores formation's original permeability, or bypasses near wellbore damage by creating wormholes that connect the wellbore to the undamaged flow network.

Unlike fracking operations, matrix stimulation operations are pumped at pressures that are less than the fracture pressures of the formation.

Due to the maturing of several giant fields and the depletion of reservoirs with high permeable rocks, advances in drilling and completion technologies led to the development of low permeable reservoirs by drilling long horizontal laterals to maximize contact with those reservoirs.

To control flow from or injection into those formations, smart completions with control devices or limited entry liners were designed to provide the required flow diversion.

As a result, modelling matrix stimulation operations on extended reach wells has become very critical, as it now entails the pumping of large volumes of treatment fluids at high rates and pressures. Moreover, a prediction of those large volumes distribution along the long lateral is key to the success of the operation.

StimDesigner Input

Streamlined Job Creation and Data Entry for Matrix Stimulation Operations

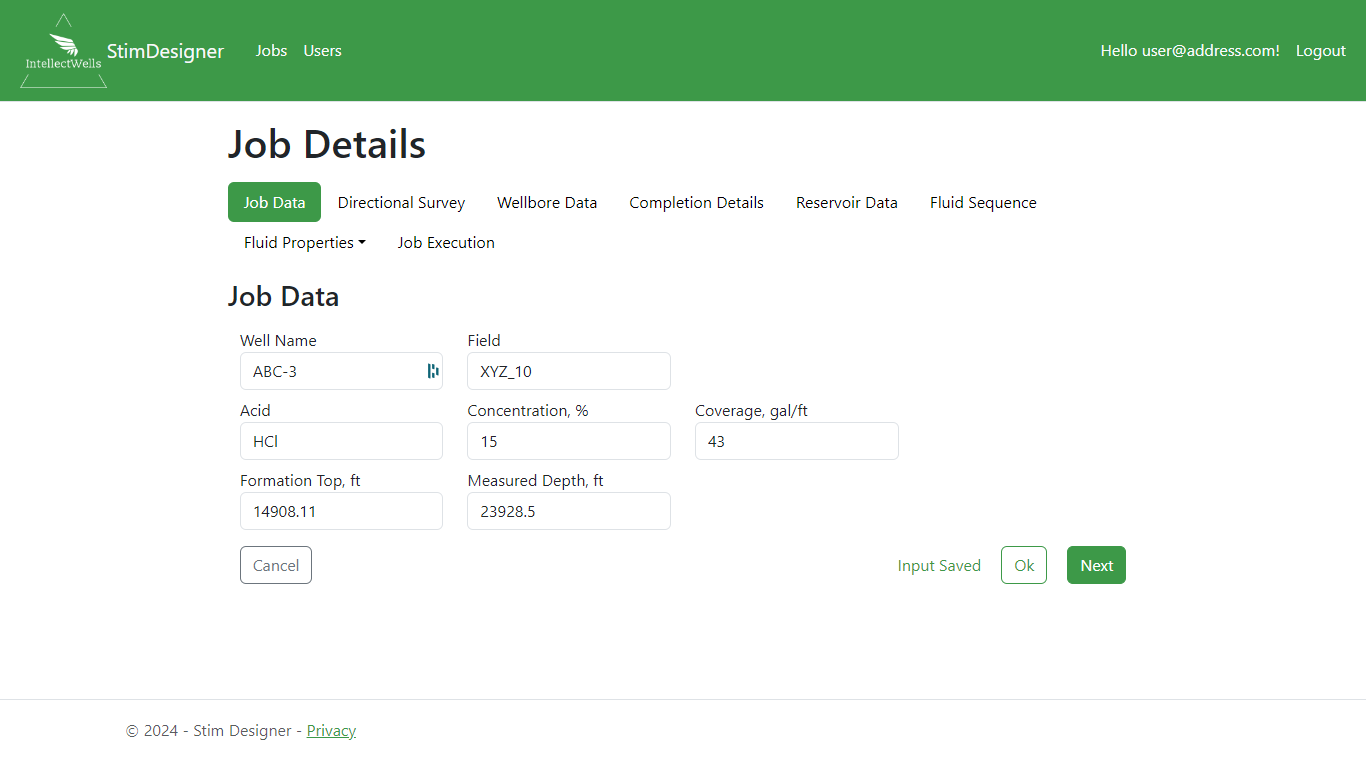

Once logged in, the user is taken to StimDesigner’s “Jobs” page where he/she can either create a new job or edit or clone an existing one.

Once the user accesses input interface for a particular job, StimDesigner allows him/her to enter general job data, wellbore data, fluid pumping sequence and job execution details manually.

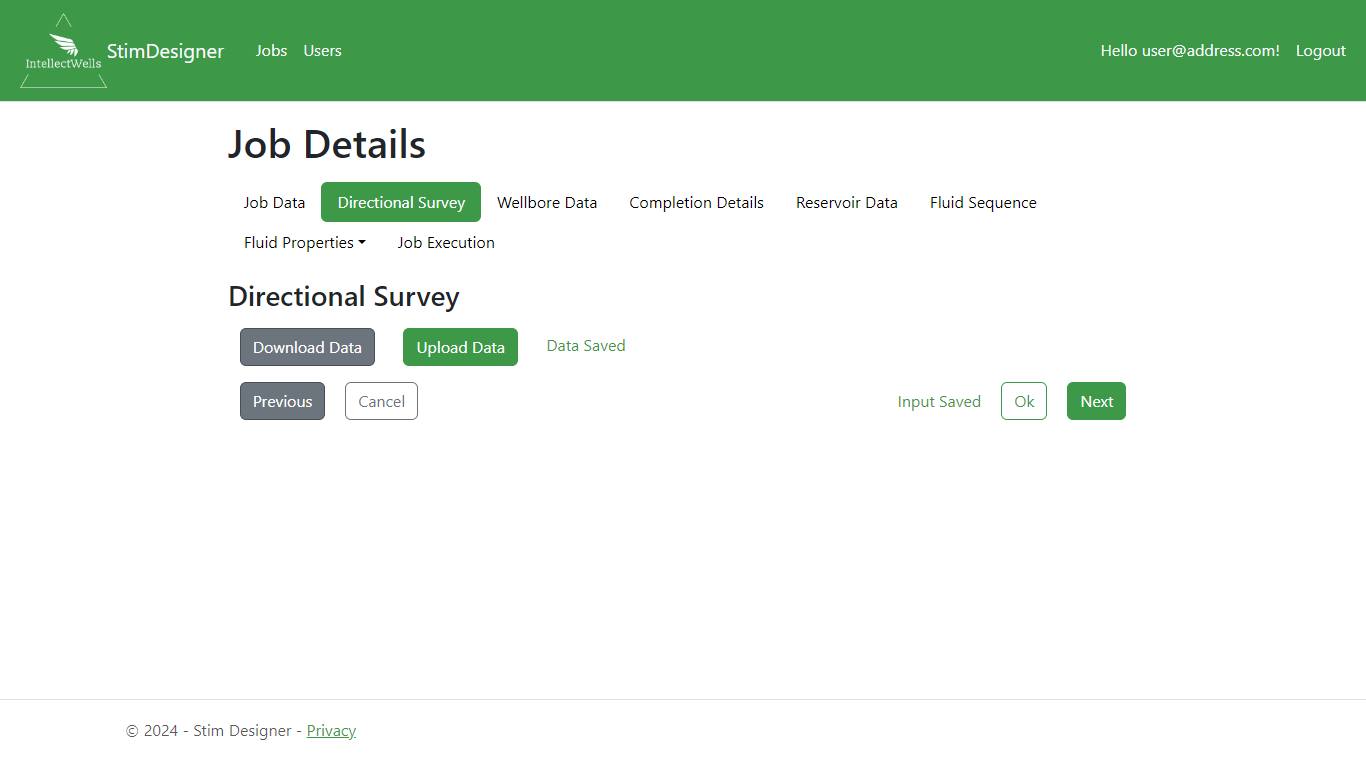

Other information; like well directional survey, reservoir logs, completion details, fluid rheology, fluid recipes and fluid friction data; can be imported as CSV files.

Using program built in downloadable templates, the user can copy the data into those templates before uploading them back into StimDesigner.

StimDesigner Output

Comprehensive Output Analysis for Matrix Stimulation Operations

With the input data fully entered, the user clicks the “Finish” button, and shortly after, the output is ready for him/her to check and evaluate.

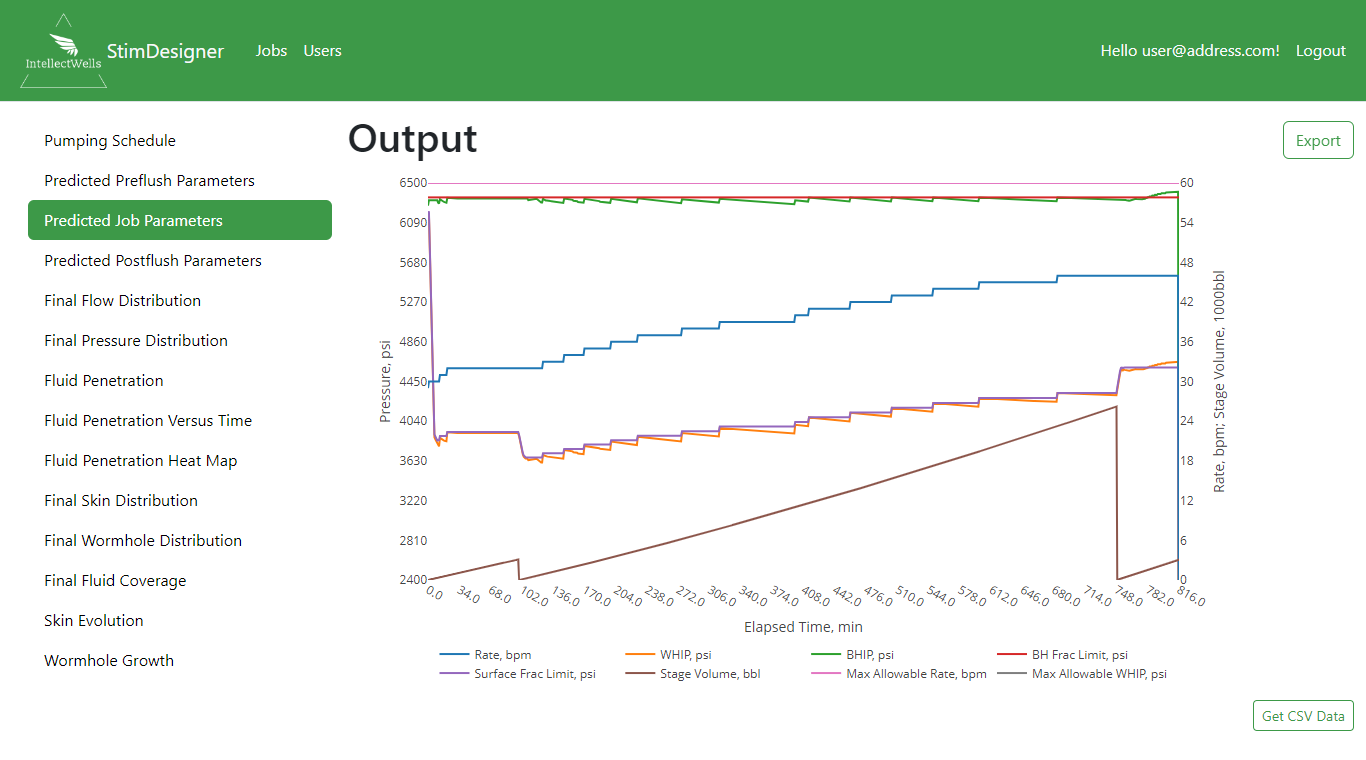

Based on initial injection rate and frac limits set by the user, StimDesigner calculates the maximum achievable rate at each time and depth increment, along with all associated job parameters. It produces an interactive plot showing rates, surface and bottomhole injection pressures, pressure limits and stage volumes as functions of job elapsed time.

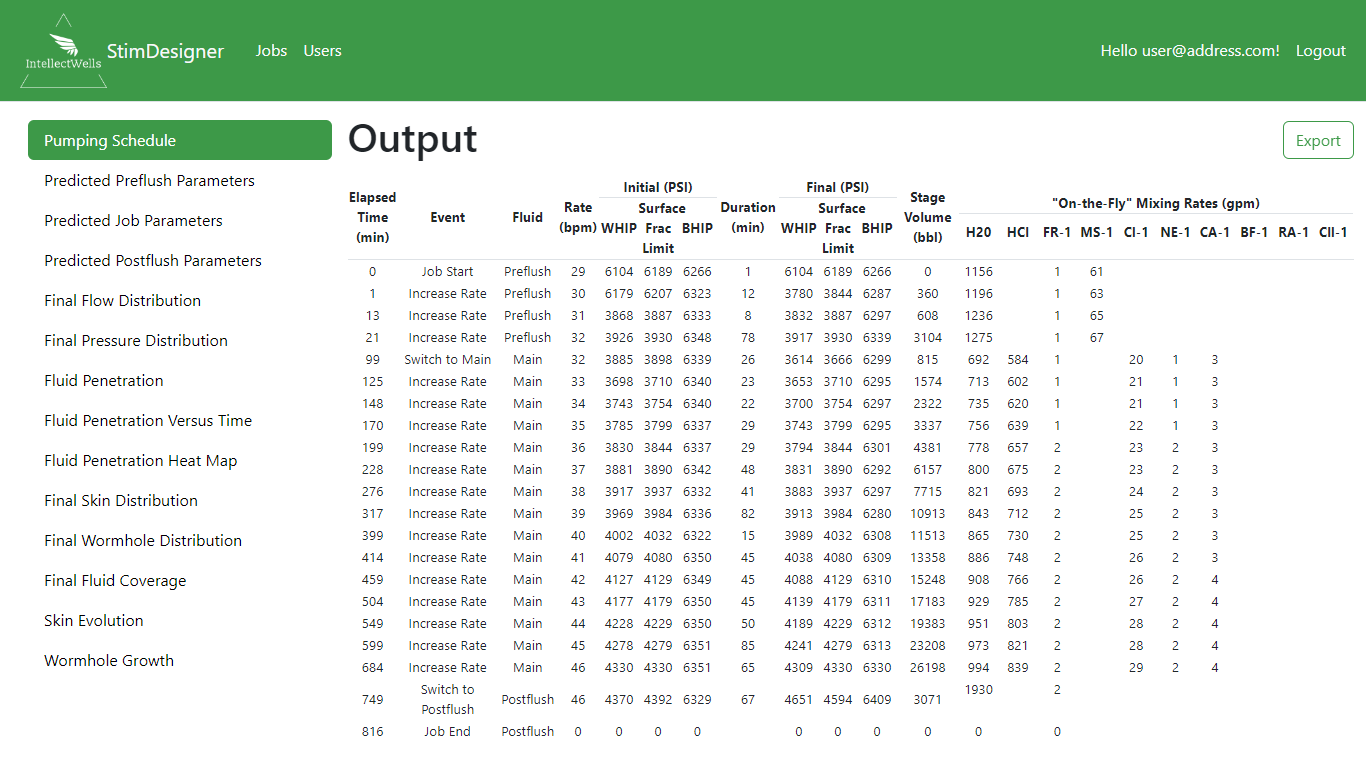

StimDesigner then generates a pumping and mixing schedule, complete with job events, event duration, anticipated job parameters and chemical additive mixing rates associated with each job event.

The anticipated maximum rates and surface pressures allows the user to make decisions regarding surface lines sizes and pressure control equipment requirement respectively. Anticipated job duration will have an impact on selected fluid recipes.

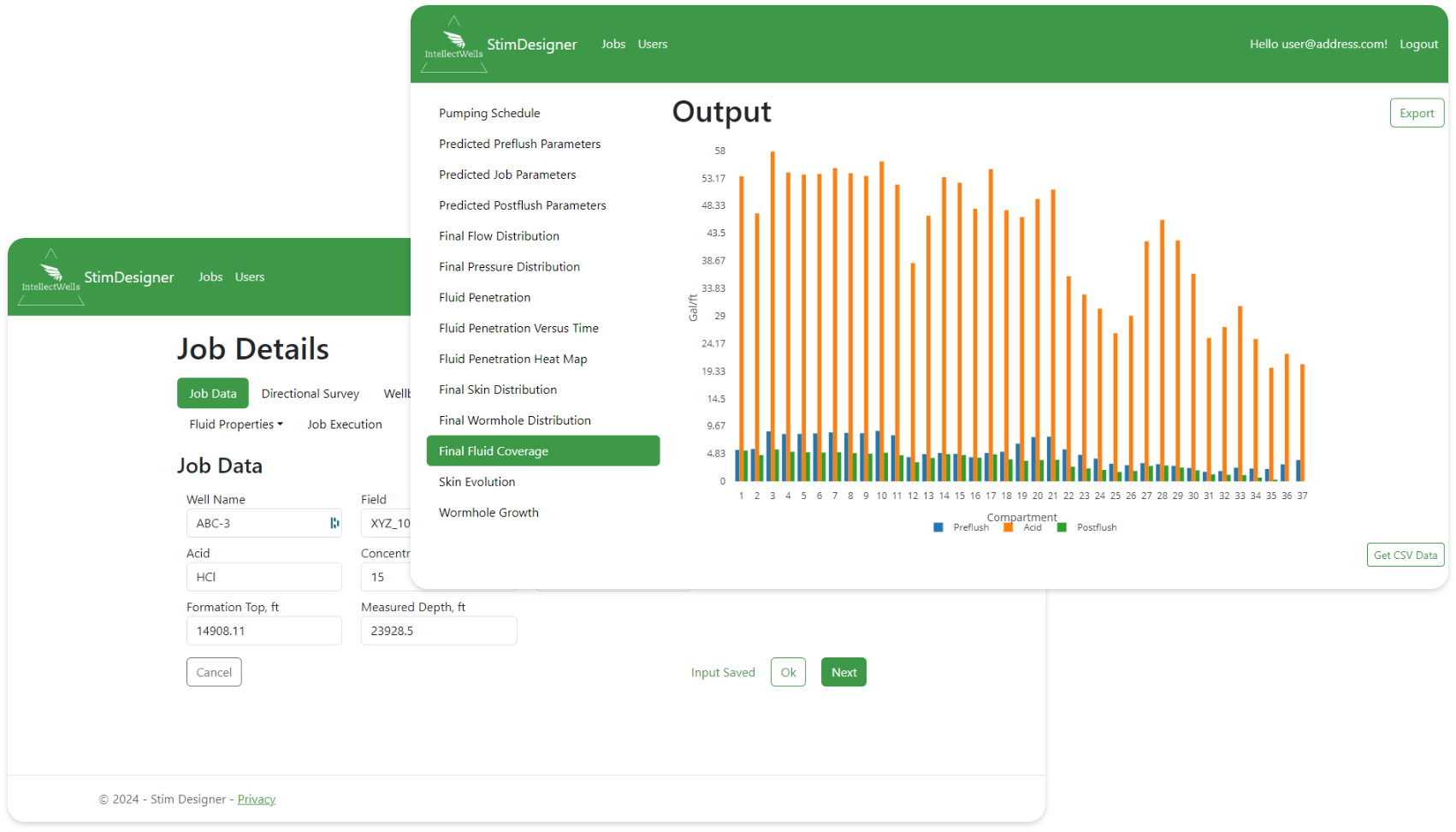

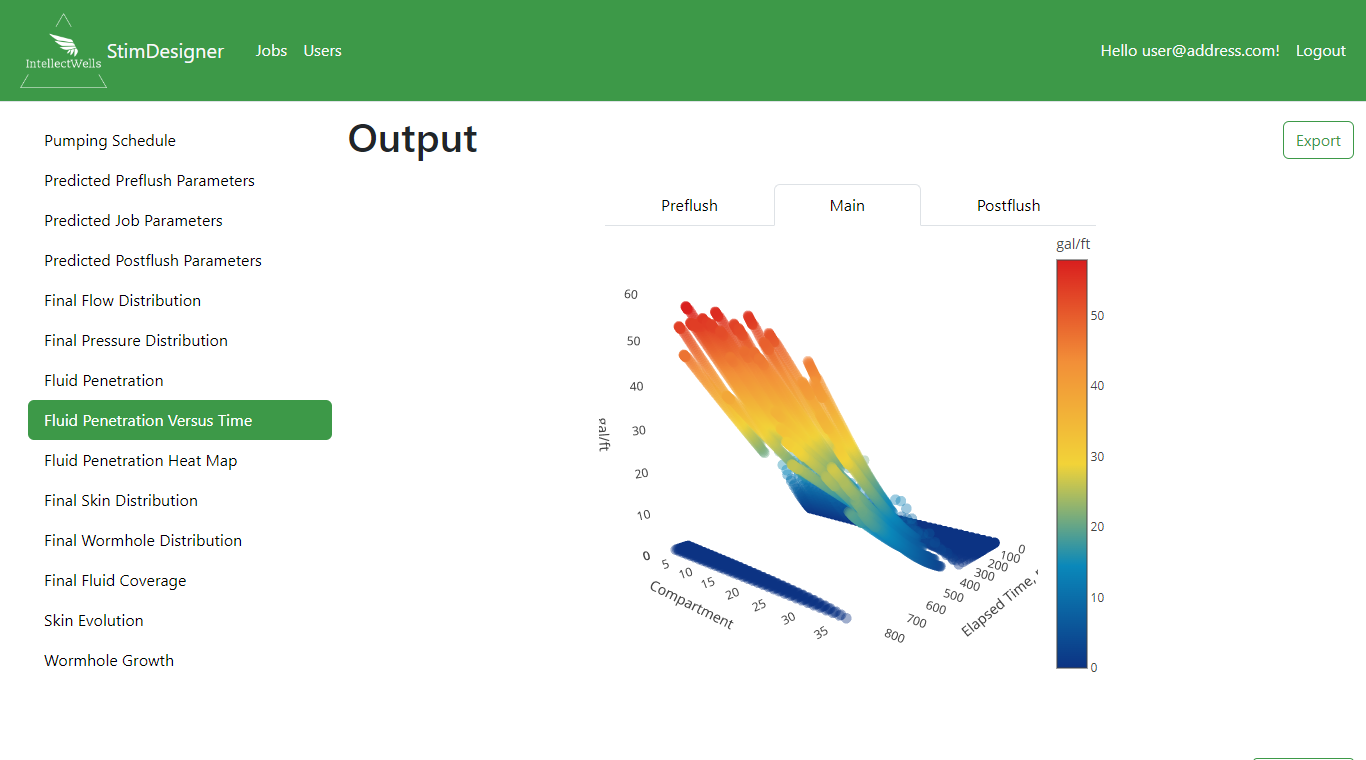

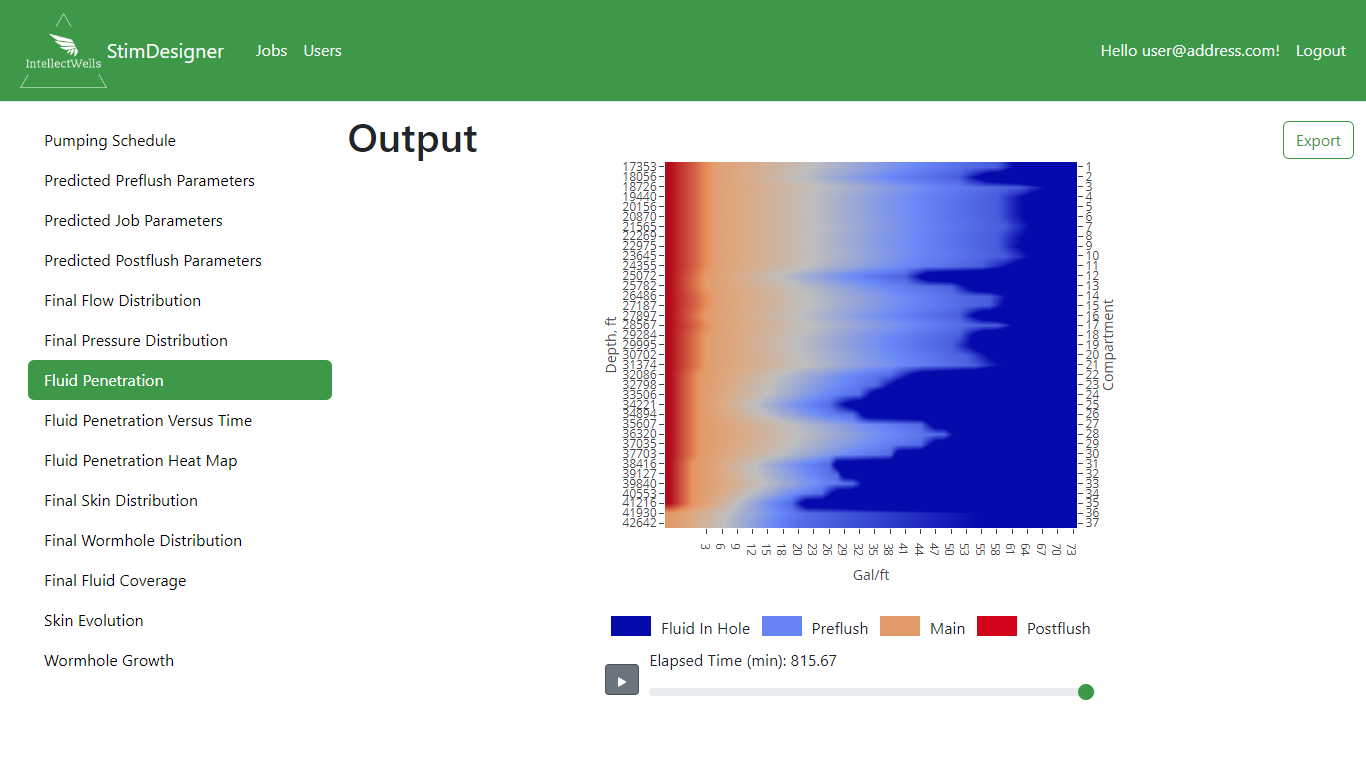

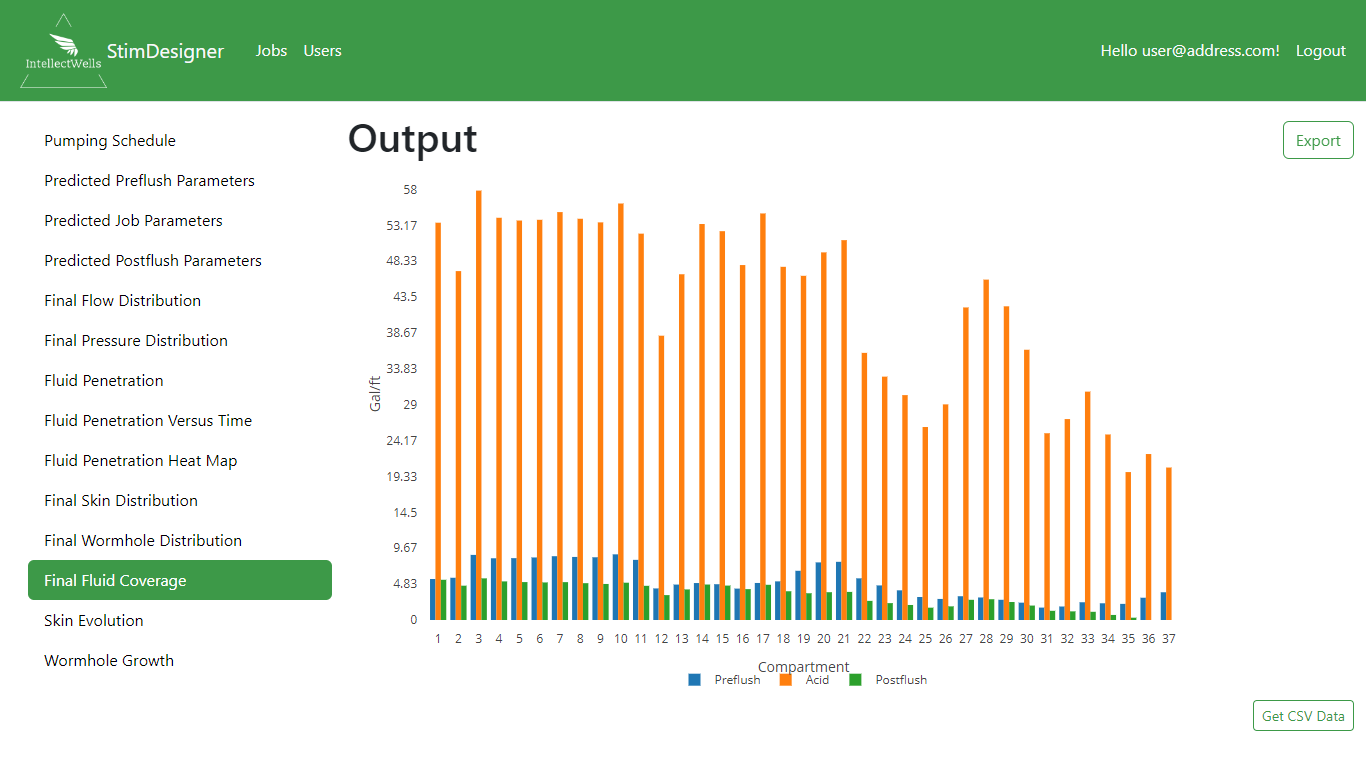

Based on flow distribution at each time and depth increment, StimDesigner calculates stage volumes and produces an interactive 3D plot showing fluid coverage in gal/ft as functions of elapsed time and depth for each pumped fluid.

The user has the option, as well, to access the raw data used to generate those plots in csv format. That feature allows the user to process the software generated raw data the way he/she wishes using other applications on his/her local machine.

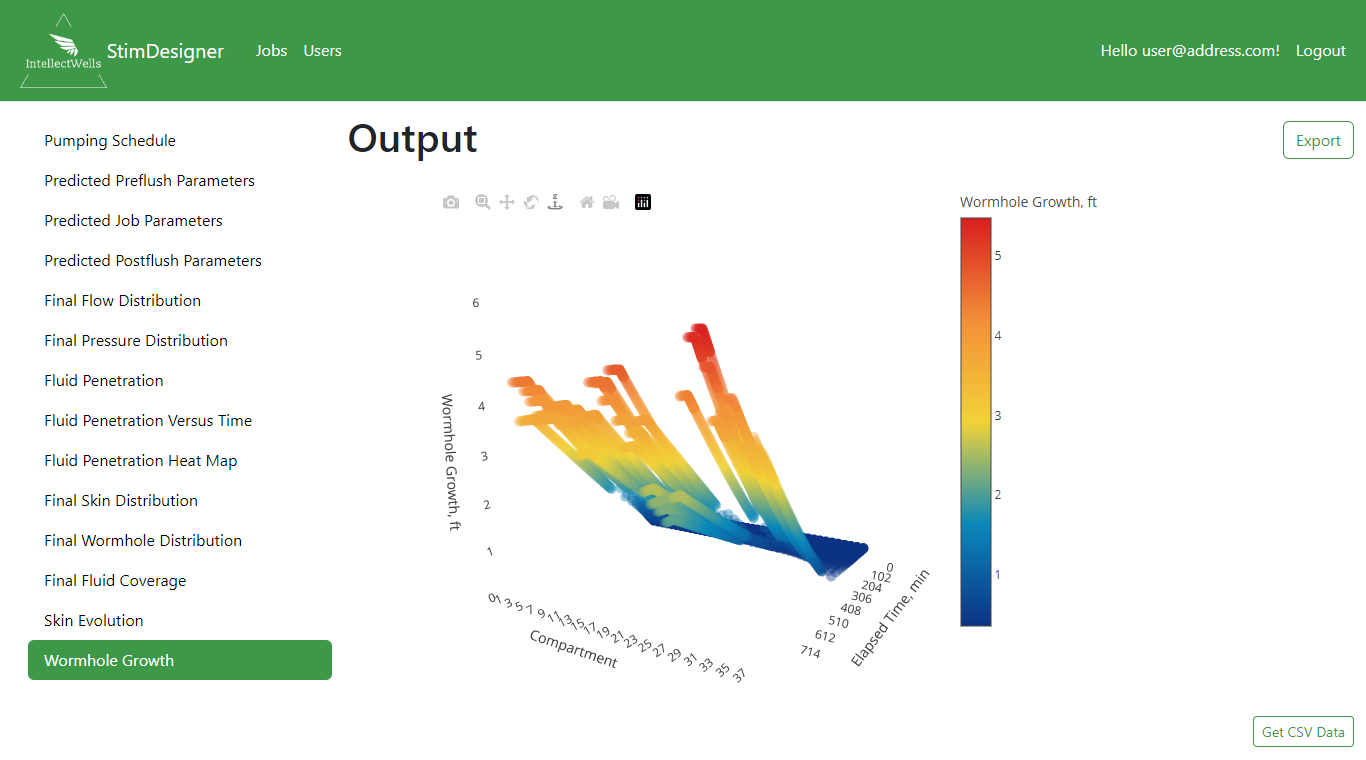

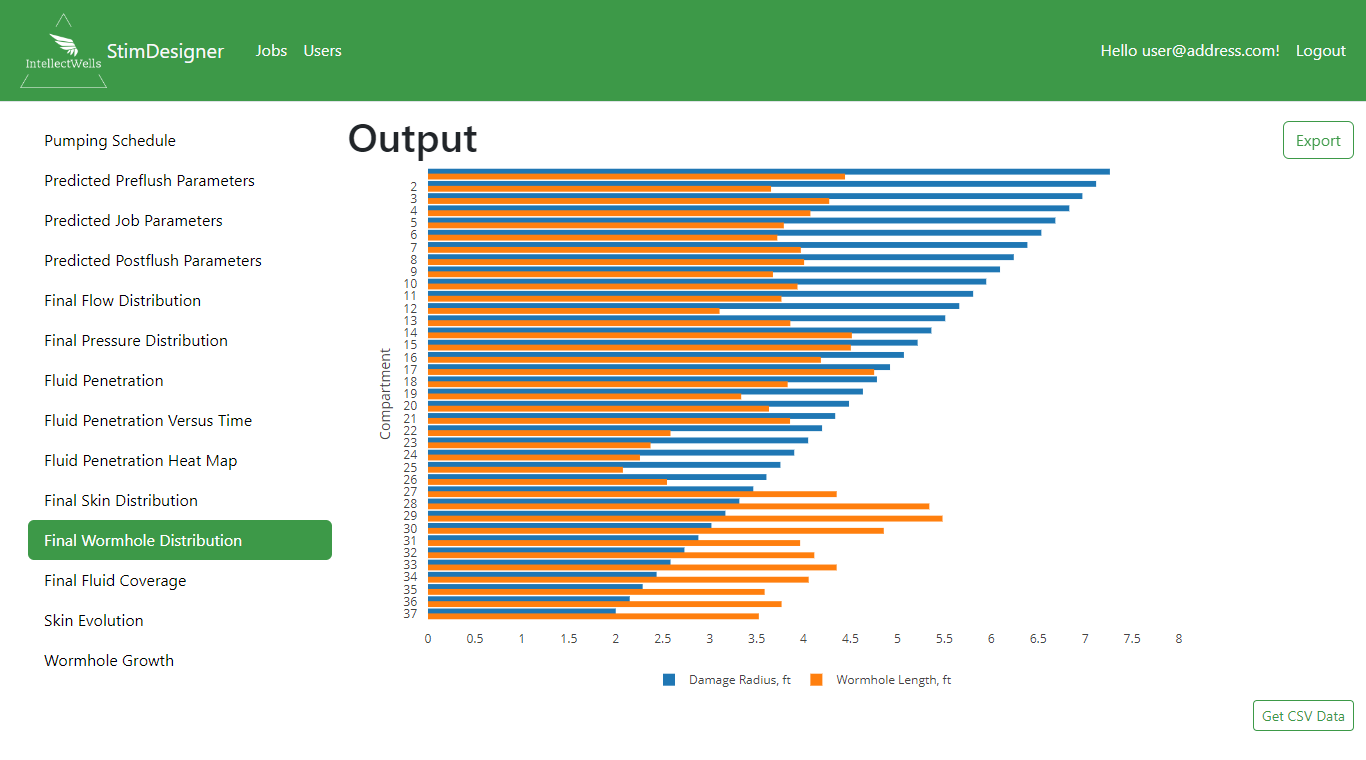

StimDesigner utilizes reservoir properties, reservoir logs and core test results to calculate wormhole length at each time and depth increment and produces an interactive 3D plot showing wormhole growth as a function of elapsed time and depth.

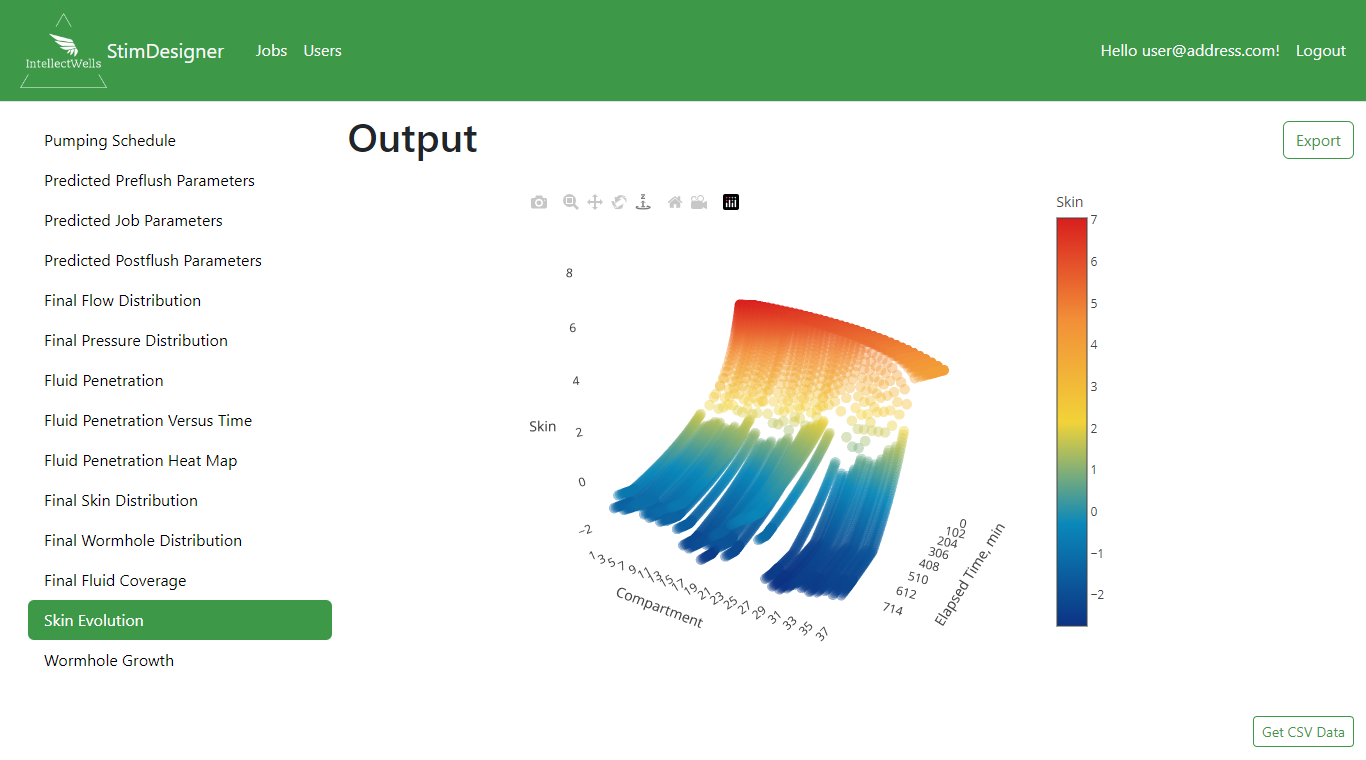

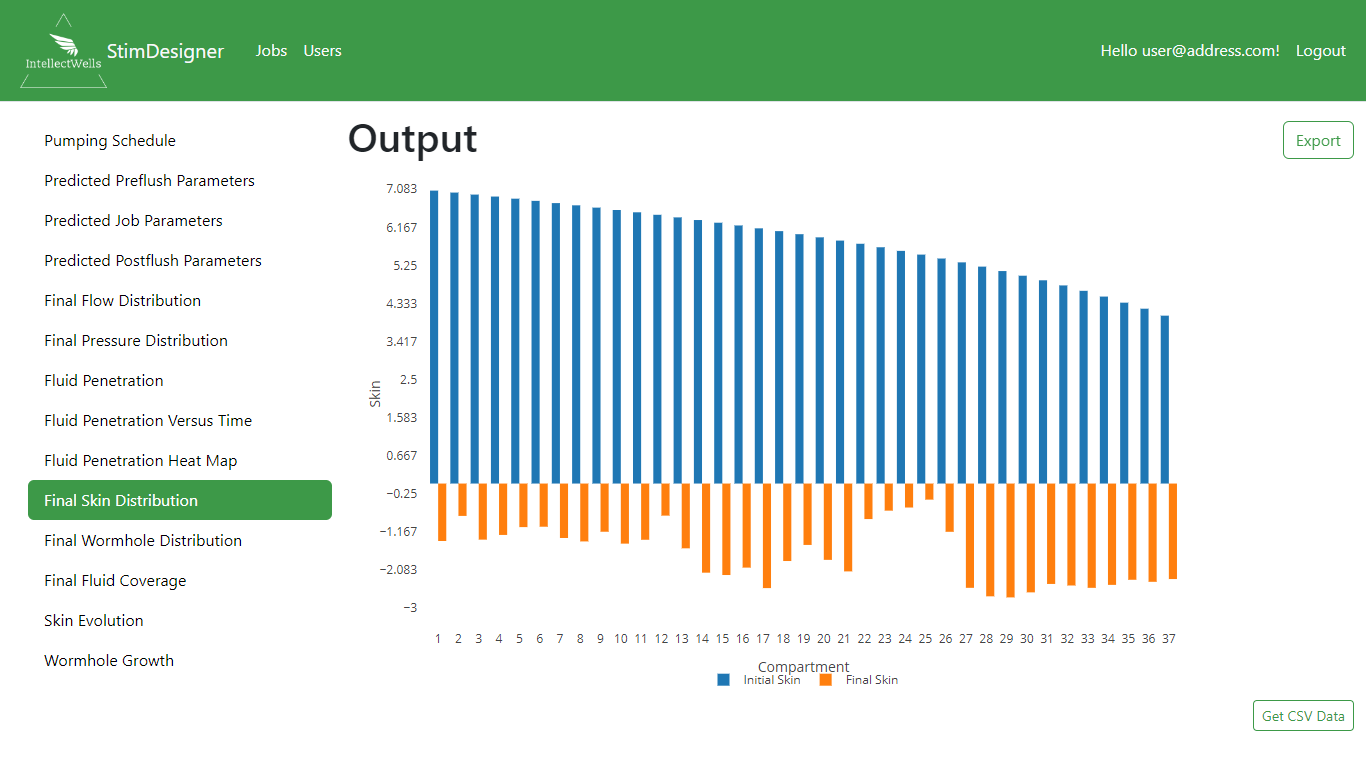

By illustrating skin evolution as a function of elapsed time and depth, StimDesigner allows the user to determine the point in time at which the target skin has been achieved and consequently make a decision regarding job fluid requirements.

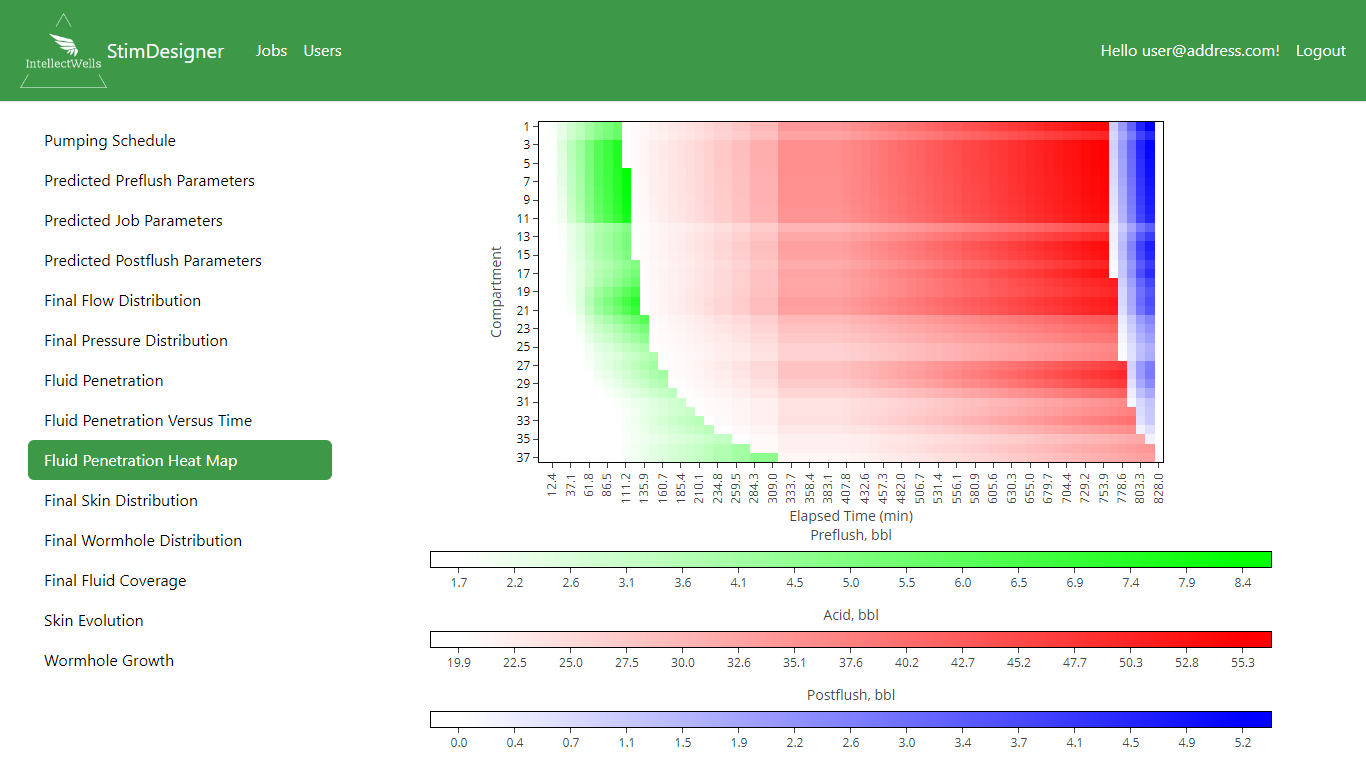

As part of the output, StimDesigner generates a heat map showing a snapshot of the final fluid penetration across the entire lateral as a function of elapsed time.

Different fluid displacement interfaces are clearly visible, illustrating the time delays each lateral section experiences in receiving a certain type of fluid.

StimDesigner enables the user to play back the entire simulated job and see when and where the penetration of each fluid took place.

It also gives the user the ability to take a snapshot of fluid penetration at any point in time during job execution.

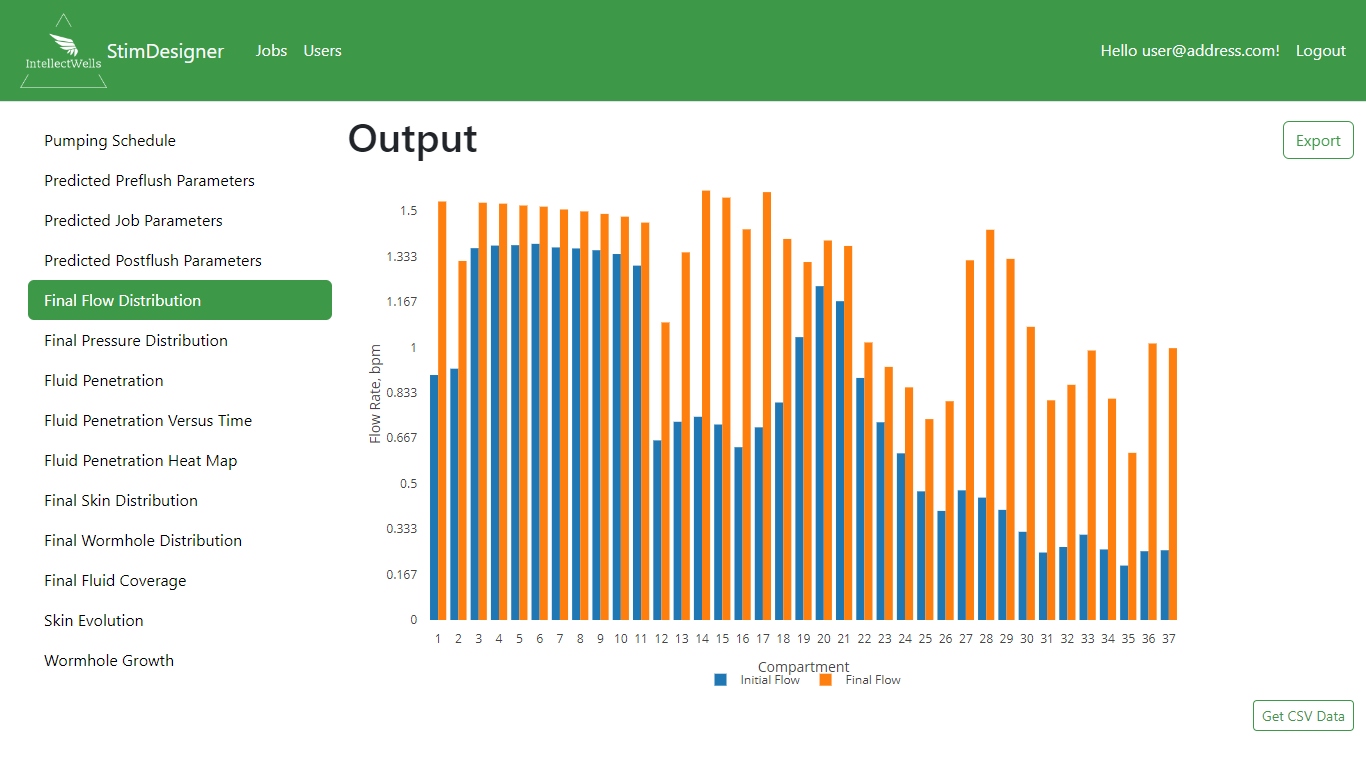

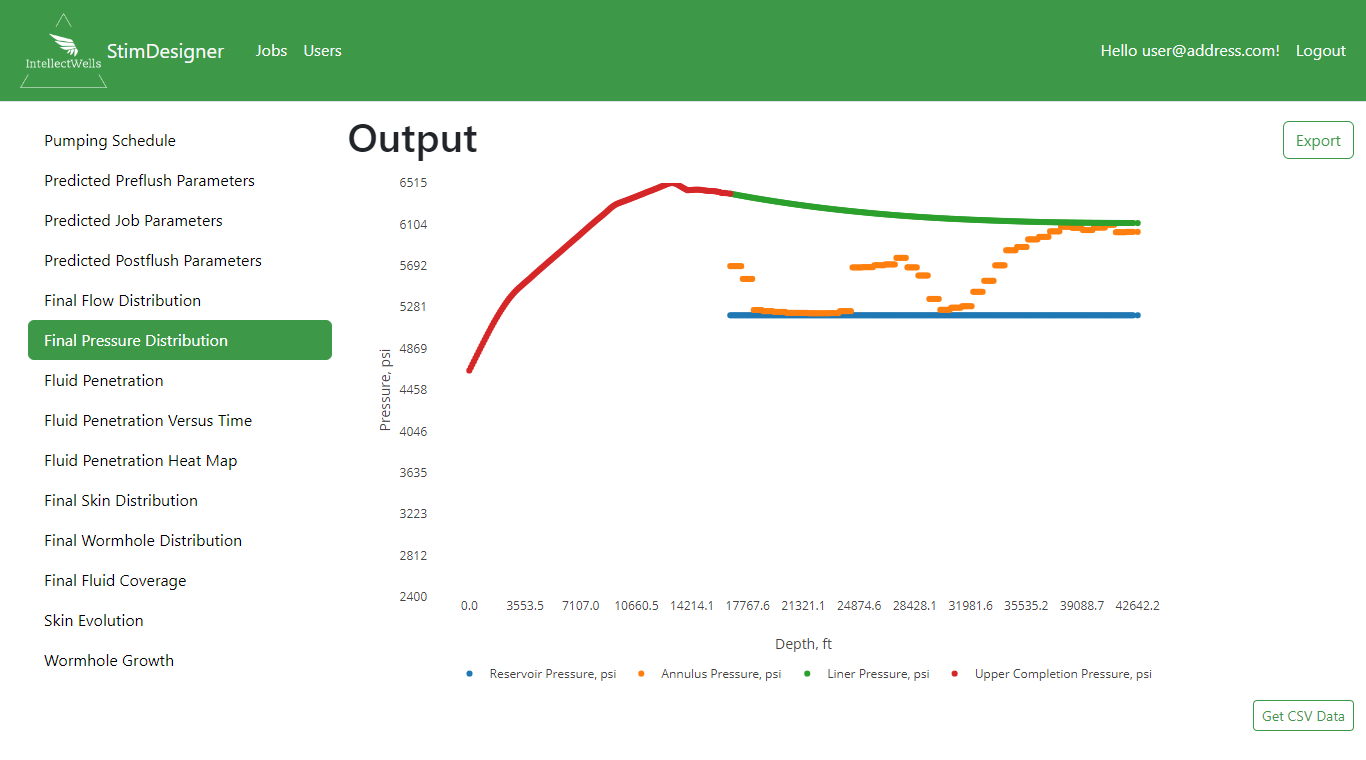

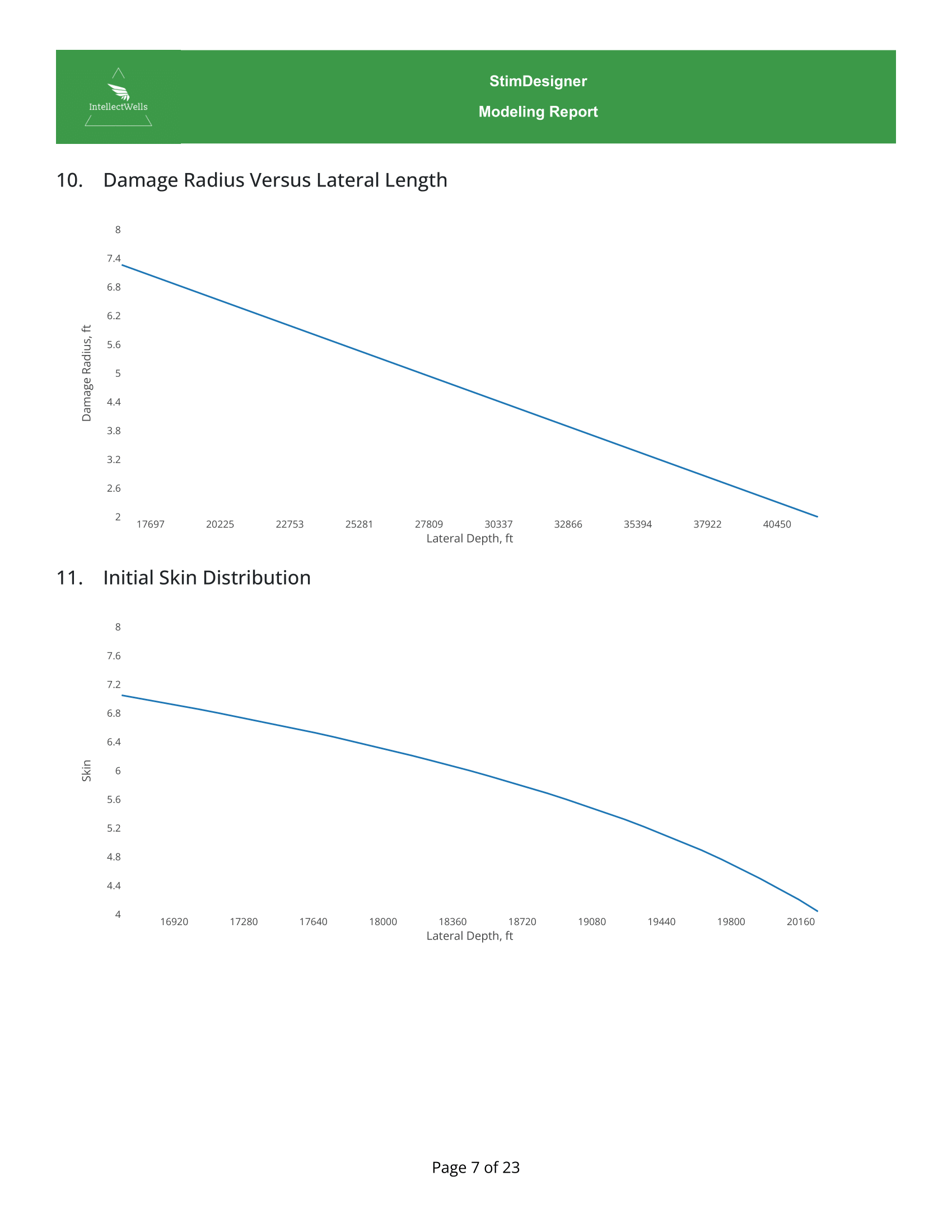

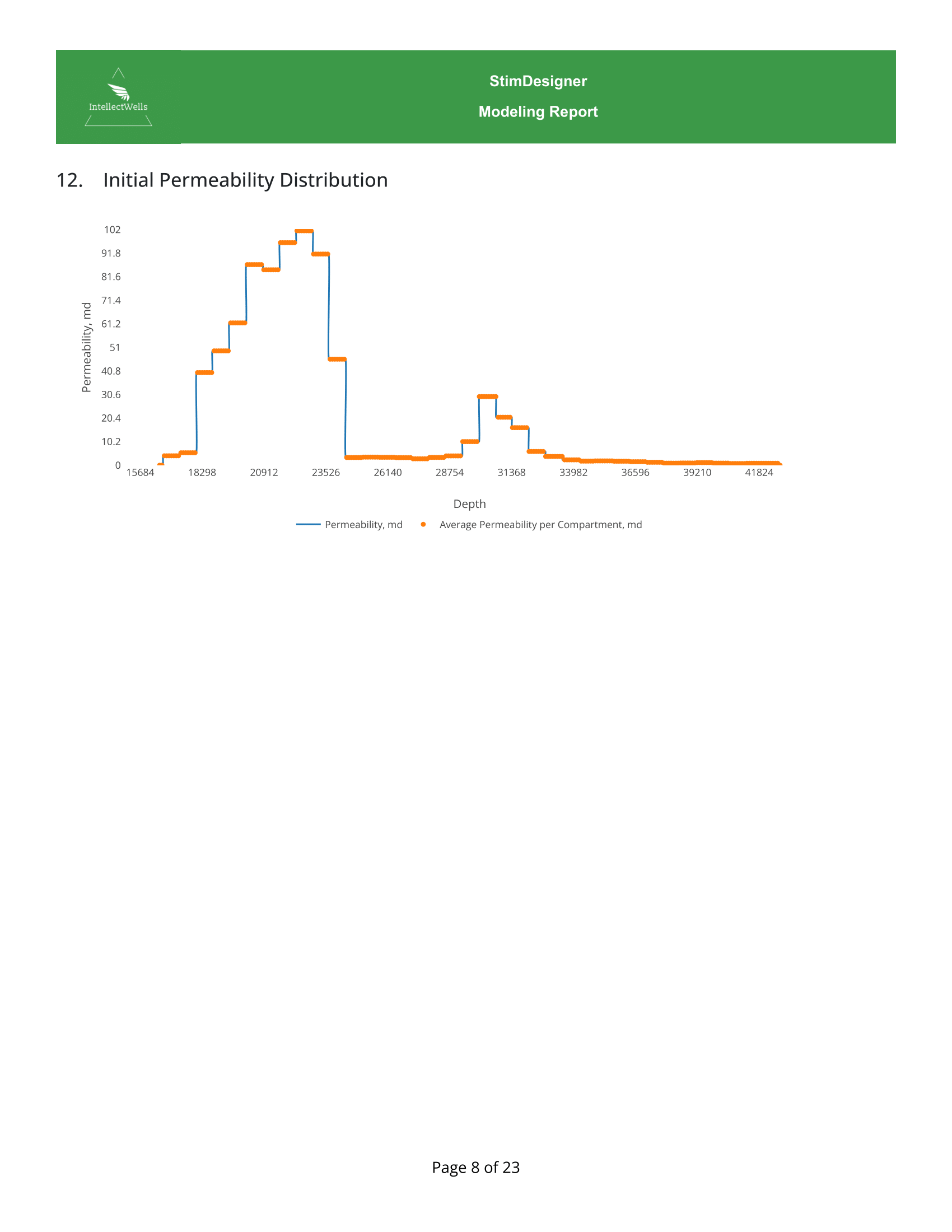

Other outputs include the final distributions along the lateral length of flow, liner pressure, annulus pressure, wormhole length/damage radius, initial/final skin, and fluid coverage in gal/ft for each fluid pumped.

StimDesigner Report

Streamlined Report Generation for Matrix Stimulation Operations

Once the generated output is checked and evaluated by the user, he/she has the option of either go back to the input interface to make changes and re-run the simulator or click the “Generate” button and produce a fully detailed pdf report, inclusive of all input and output data.

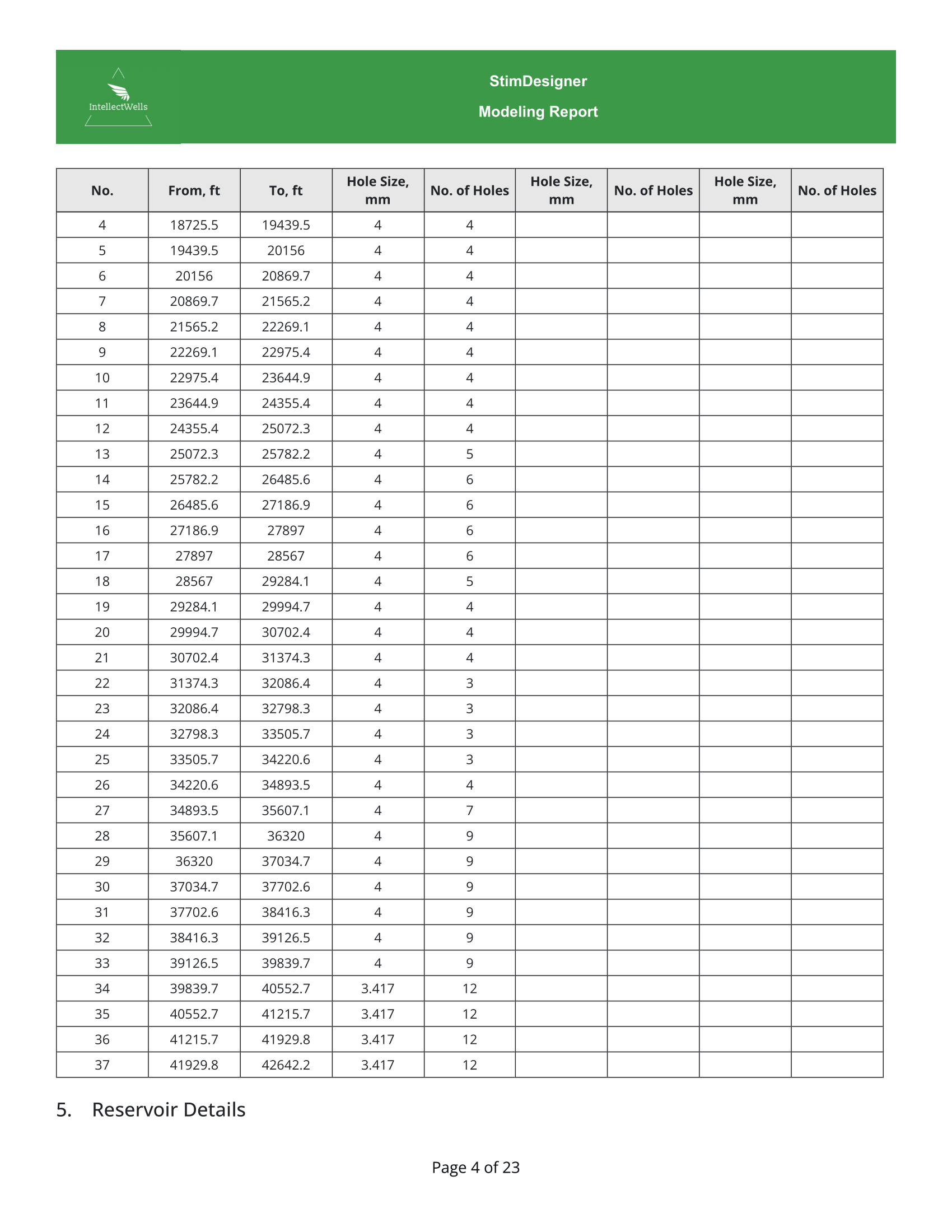

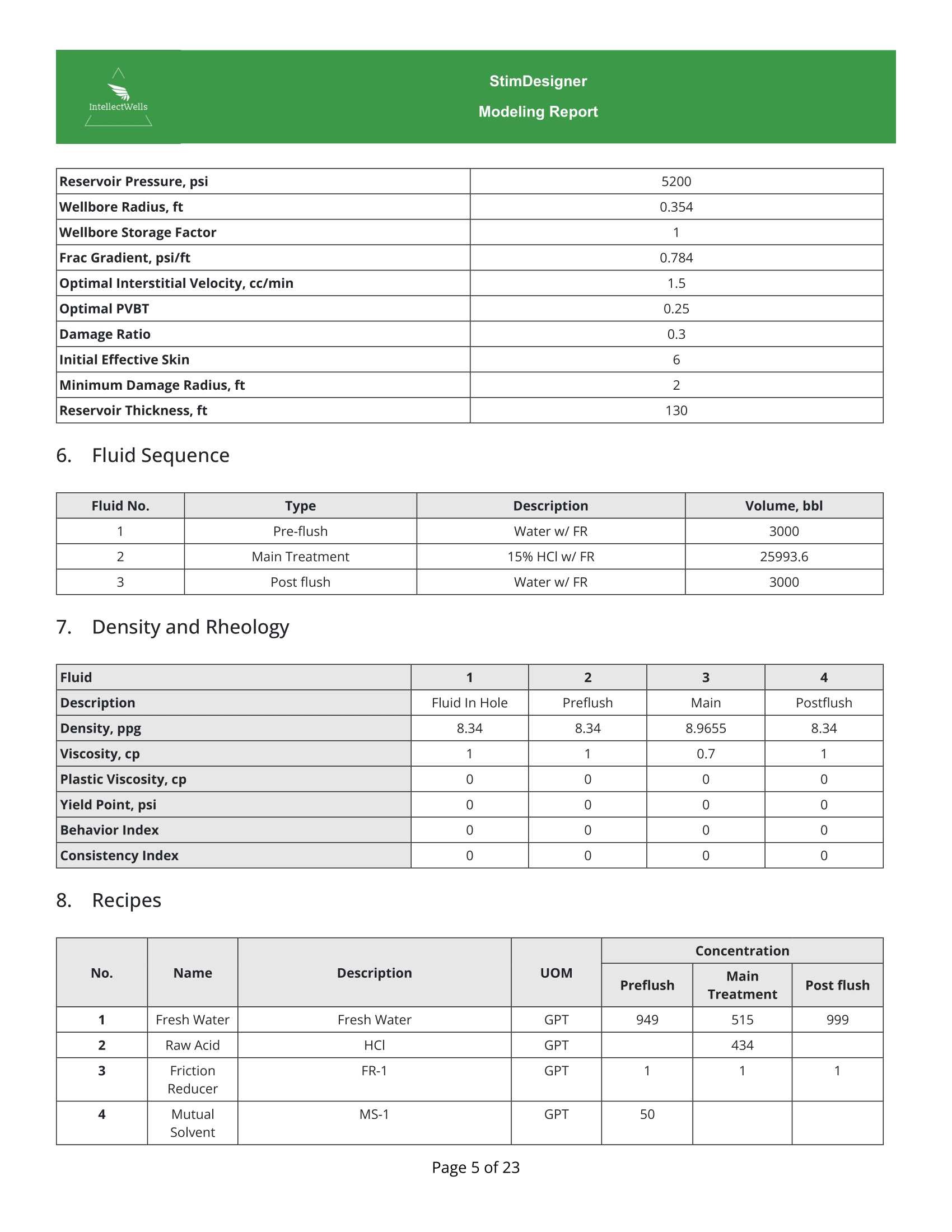

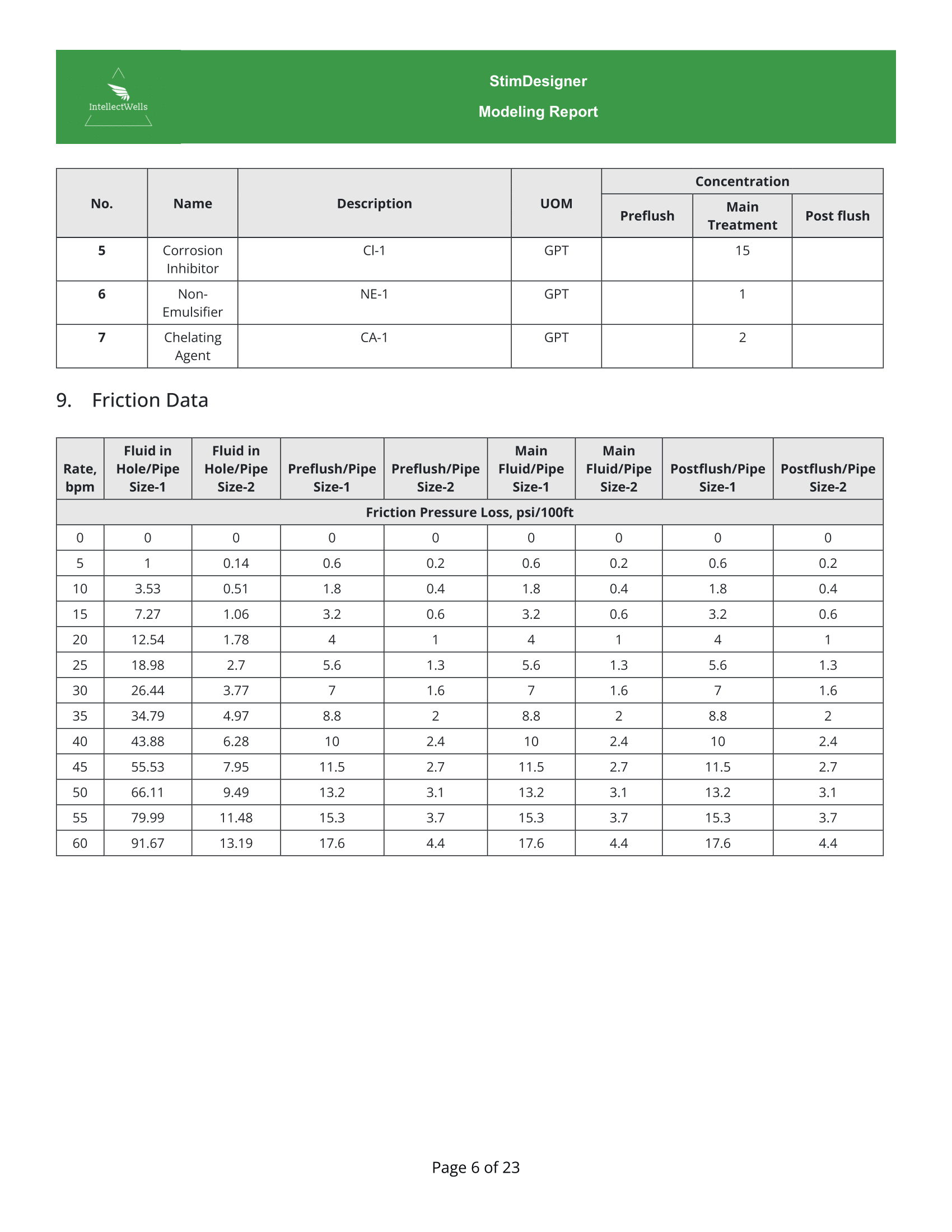

A few example pages of the generated report are illustrated below:

Contact Us

To learn more about how StimDesigner can optimize your oil and gas production operations, please fill out the contact form or email our support team directly at info@intellectwells.com or technicalsupport@intellectwells.com.

An asterisk (*) indicates a required field